Description

Glasswool blankets are manufactured from a unique rotary flame attenuation process incorporating highly resilient, inorganic glass fibres bonded with a thermosetting resin to form a lightweight, flexible and resilient insulation material. Apart from providing good thermal insulation qualities, it is also an effective sound absorption material. The glasswool blanket also can be coated with facing, such as alu foil, fiber cloth, polypropylene, fiber tissue etc. according to the requirements of different uses.

Also we accept OEM for different brands of products based on requirements of customers.

Advantages

l Unique technology, rebound degree after compressive packing is up to 99.2%

l Soft and long glass fibers can maximally lessen flying catkins in the construction

l Sound absorption and noise reduction, it can effectively prevent sound from spreading

l Grade A1 incombustible materials

l Easy for construction, cutting at will

l Antisepsis, ageing resistance, and anticorrosion, ensuring a healthy environment

l Low moisture absorption, stable physical properties

Specifications/Sizes

Density | 10-48kg/m3 |

Sizes | Length | 8-32m |

Width | 1.2m |

Thickness | 25~200mm |

Remarks: For more detailed specifications information, please contact us.

A variety of moisture-proof facings can be stuck on the surface of galsswool.

Technical Date

l Basic Technology Parameters

Item | Index | Measured value | Standard |

Bulk density (kg/m3) | 10-96 | 10-96 | GB/T 13350-2000 |

R-values * | - | R1.3-5.0 |

Average diameter of blankets (µm) | <8.0 | 4.0-6.0 |

Moisture resistivity (%) | >98 | >98.5 |

Thermal conductivity (W/m.K) * | 0.049-0.042 | 0.045-0.032 |

Incombustibility | Incombustible | Up to standard (Grade A) |

Water absorption | - | in 24 hours short term <1KG/m2 in 28 days long term <3KG/m2 |

Resistance to Water vapor | - | 7.00 MN.s.g.m |

Sound absorption coefficient | - | 1.03 product reverberation positioning 24kg/m3 2000HZ |

Max. working temperature(℃) | 400 | 410 |

l Physical Properties

Item | Standard | Detailed |

Shrinkage temperature of heat load | GB/T11835-1998 | 250~400℃ |

Corrosion resistance | ASTM C665 | No chemical reaction |

Mildew resistance | ASTM C665 | Mildewproof |

Performance | Experimental method | Technical requirements |

Moisture absorption | ASTM C1104 GB 5480.7-87 | ≤3% of weight(49℃,relative humidity 90%) ≤5% of weight(49℃,relative humidity 90%) |

Moisture permeability | ASTM E96 GB/T17146-1997 | Max.0.013g/24h•m2•mercury/mm |

Combustibility | UL723 ASTM E84 CAN/ULC S-102 GB8624 | Flame spreading:25 Flumes spreading:50 Grade A incombustible material |

l R-thermal resistance value

Bulk density(kg/m3)

Thickness(mm) | 12 | 14 | 16 | 20 | 24 |

50 | 1.22 | 1.32 | 1.36 | 1.43 | 1.47 |

75 | 1.83 | 1.97 | 2.03 | 2.14 | 2.21 |

100 | 2.44 | 2.63 | 2.70 | 2.86 | 2.94 |

Remarks: R-thermal resistance value=thickness/thermal conductivity (unit:m2•℃/W)

Conversion formula of British thermal resistance:1h•ft2•H/Btu=5.678m2•℃/W

Data sources: test report of National Supervision and Test Center for Product Quality of glass fiber products

l Changing table of density and thermal conductivity

10kg~48kg partial

l Design of sound absorption

The requirements of buildings on sound absorption should be calculated according to the following acoustical property of glasswool felt to determine product specifications.

Sound absorption coefficient (glasswool felt with facing)

Applications

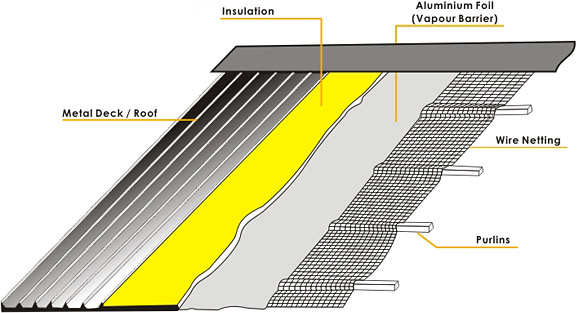

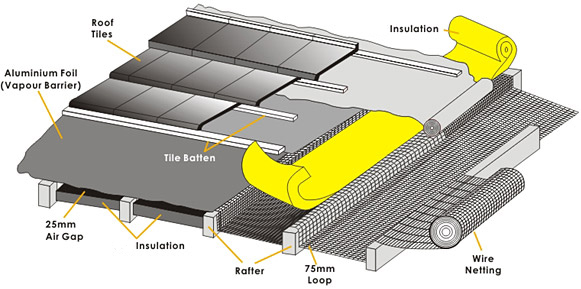

Glasswool Blanket is commonly used for the underside of metal roofing in industrial projects for insulation purposes. It can also be extensively used for all types of residential and commercial projects. The glasswool can either be installed between the roof trusses or just above the ceiling. Single sided or double sided aluminium foil has to be placed below the glasswool blanket for vapour barrier application.

Conventional Construction On Metal Deck Roofing

Residential Roof Tile Insulation

Packing, Loading Quantity

l8-32 m/roll, 1-2 roll overlapping

lvacuum with PE/PP/Thermal shrinkage film

lAll of glasswool blankets adopt transparent water-proof packing for convenient direct-viewing. To meet the need of requirements of logistics distribution, the products adopt new technology in compression and packing strength and etc. Compression ratio is 1:8.4.

Certifications

l GB/T19002-1994, ISO9002-1994

l AS/NZS4859.1

l SGS

l EU CE