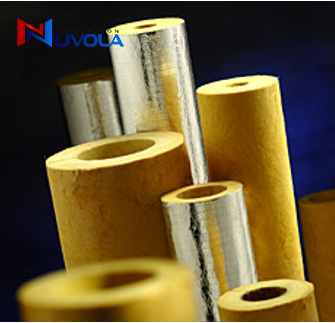

NUVOLATM Glass Wool Pipe Insulation is a one-piece molded insulation made from glass fibers bonded with a thermo setting resin. Glass wool pipe insulation is for hot and cold pipes in one metre length. It is designed to fit pipes of external diameter of 1/2"(23mm) to 32"( 815mm) with insulation thickness of 1/2"(13mm) to 4"(100mm) while other sizes are available upon request. Density ranges from 64kg/m3 to 96kg/m3. Pipes are split longitudinally to provide ease of installation. For application where vapour barrier are needed, pipes faced with aluminum foil or ASJ jacket are available.

Advantages

1. Excellent thermal performance;

2. Easy to handle and fabricate;

3. Low cost installation;

4. Good compressive strength;

5. Non combustible;

6. Vapor Retarder Jacket.

Standard Specifications

Density(kg/m³) | Thickness(mm) | Diameter(mm) | Length(mm) |

48, 64, 80, 100 | 13~100 | 23~815 | 915, 1000 |

Note: Other sizes, density are available.

Choice of facings: Aluminum foil or ASJ jarket

Accessories: We can be attached to the Double-sided Adhesive, allowing you to install. We also can supply Aluminum Foil Tape.

Technical Data

Items | Standard | Performence |

Service Temperature | ASTM C 411 | From -18℃(0°F) to +454℃(850°F) |

Surface Burning Characteristics | ASTM E-84 | Flame Spread 20 Smoke Developed 30 |

Water Vapor Transmission | ASTM E-96,Procedure A | Jacket has water vapor permanence of 0.02 perm or less |

Corrosiveness | ASTM C 665 | No greater than sterile cotton |

Stress Corrosion | ASTM C 795 | Complies with standard |

Alkalinity | ASTM C 871 | Less than 0.6% as Na2o , PH between 7.5 and 10.0 |

Microbial Growth | ASTM C1338 | Does not promote microbial growth |

Water Vapor Sorption | ASTM C1104 | Less than 0.2% by volume |

Linear Shrinkage | ASTM C356 | Negligible |

Bursting Strength of Jacket | ASTM D774 | 80psi |

Puncture Resistance of Jacket | ASTM C1136 | 60 Beach Units |

Thermal Conductivity Chart

Mean Temp °F | 100 | 200 | 300 | 400 | 500 |

”k”BTU in/ft2h °F | 0.226 | 0.286 | 0.356 | 0.434 | 0.524 |